Turn PPE Waste Into No Waste With Responsible Disposal Practices

The rising use of personal protective equipment (PPE) since the COVID-19 pandemic has led to unprecedented amounts of waste. Learning how to effectively manage PPE waste is essential to protect our environment, conserve resources, and promote sustainability. In this comprehensive guide, we'll walk you through strategies to turn PPE waste into no waste through responsible disposal and innovative re-use techniques.

Understanding PPE Waste and Its Environmental Impact

The global demand for PPE like masks, gloves, gowns, and face shields has soared in recent years. Unfortunately, most of this equipment is designed for single use and is often made from non-biodegradable materials such as polypropylene and polyvinyl chloride. As a result, the improper disposal of PPE not only contaminates landfills but also contributes to marine pollution, putting wildlife and human health at risk.

- Single-use masks can take up to 450 years to break down in the environment.

- Improperly discarded gloves and gowns can clog sewage systems.

- PPE waste is often contaminated by pathogens, adding a biohazard element to its environmental footprint.

PPE waste management is therefore not just a matter of public cleanliness; it directly affects ecological health and sustainability efforts worldwide.

What Is Responsible Disposal of PPE?

Responsible disposal refers to managing and disposing of personal protective equipment in ways that minimize environmental harm, reduce health risks, and support recycling or upcycling initiatives. This approach transforms the idea of "waste" into a resource waiting to be harnessed, moving us closer to zero PPE waste goals.

Key Aspects of Responsible PPE Waste Disposal

- Segregation: Separating PPE waste from general waste streams at the source.

- Decontamination: Treating used PPE to neutralize any pathogens.

- Recycling and Upcycling: Converting suitable PPE materials into new products or raw materials.

- Proper Collection: Utilizing designated bins and safe handling protocols.

- Education: Informing users and staff about correct disposal procedures.

Best Practices to Turn PPE Waste Into No Waste

Considering the environmental hazards, individuals and organizations must adopt sustainable PPE waste disposal practices. Below are effective methods you can implement to help reduce, reuse, and recycle PPE waste:

1. Source Reduction: Minimize PPE Consumption

The first step in reducing PPE waste is to minimize its use where possible without compromising safety. Strategies include:

- Investing in Reusable PPE: When suitable, opt for protective gear designed for multiple uses, such as washable cloth masks and durable face shields.

- Efficient Stock Management: Properly forecast PPE needs to prevent over-purchasing and wastage.

- Staff Training: Regularly train workers in the correct donning and doffing procedures to avoid unnecessary contamination and disposal.

2. Segregation and Safe Collection

Segregating PPE waste from regular waste is crucial. Mixing PPE with recyclable materials or landfill waste poses contamination risks and complicates waste processing.

- Color-coded Bins: Use clearly marked, color-coded bins for PPE waste collection in workplaces, hospitals, and public areas.

- Contactless Disposal: Install bins with foot pedals or motion sensors to minimize contact and cross-contamination.

3. Decontamination of Used PPE

Before considering recycling, used PPE must undergo decontamination to destroy potential pathogens. Methods include:

- Autoclaving: Steam sterilization, commonly used in healthcare settings.

- Chemical Disinfection: Treating PPE with approved disinfectants.

- UV-C Radiation: Use of ultraviolet light to neutralize bacteria and viruses.

4. PPE Recycling and Upcycling Solutions

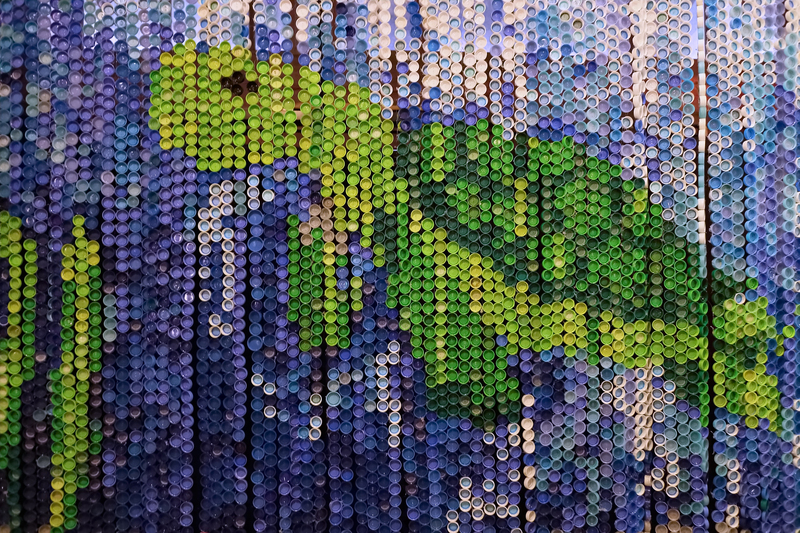

Although many PPE items are not designed for recycling, advancements in technology are making it increasingly possible to recycle PPE waste into useful products:

- Thermal Processing: Converting plastics from PPE into fuel or raw materials for new goods.

- Material Recovery: Specialized facilities can break down masks, gloves, and gowns to retrieve polypropylene fibers for use in construction panels, road surfacing, and more.

- Plastic Lumber: Some companies transform PPE plastic into lumber for park benches and other public amenities.

By supporting and incentivizing such innovations, communities can create a circular economy for PPE materials.

5. Education and Public Awareness

The success of any PPE waste reduction initiative depends heavily on public participation. Consider initiating campaigns that:

- Inform about Environmental Impacts: Share statistics and real-world examples of PPE pollution.

- Demonstrate Proper Disposal: Use signage and demonstrations to show correct disposal techniques.

- Promote Recycling Programs: Highlight local facilities or companies that accept PPE waste for recycling.

Innovative Technologies for PPE Waste Disposal

More organizations are now investing in innovative PPE waste management technologies. Some notable advancements include:

- Automated Sorting Machines: High-tech sensors separate contaminated PPE from regular recyclables.

- Pyrolysis: This thermal decomposition technology turns PPE plastics into fuels or chemical feedstocks without generating harmful emissions.

- On-site Sterilization Units: Compact devices sterilize and shred PPE for safer and easier recycling.

The integration of such technologies will play a vital role in achieving the vision to turn PPE waste into no waste at both local and global scales.

Case Studies: Successful PPE Waste Reduction Initiatives

UK NHS: Closed-Loop Recycling

The UK's National Health Service partnered with recycling firms to collect used masks, gowns, and gloves, decontaminate them, and convert recovered plastics into hospital furniture and construction boards. This closed-loop approach dramatically reduced the volume of PPE sent to landfills.

India's PPE Road Projects

Indian researchers devised a method to mix shredded PPE with asphalt for building durable roads. This innovative solution repurposes thousands of tonnes of PPE while enhancing road quality.

Circular PPE Initiatives in Australia

Australian hospitals are piloting programs to collect, sanitize, and recycle face shields and goggles for repeated use, substantially cutting down both procurement costs and waste generation.

Barriers to Effective PPE Waste Management

Even with available solutions, there are several obstacles to advancing PPE waste management globally:

- Lack of Infrastructure: Many regions lack specialized recycling plants or safe disposal sites for PPE.

- Contamination Concerns: The infectious nature of used PPE requires stringent handling and decontamination procedures.

- Public Awareness Gaps: Misconceptions about recycling, combined with convenience-driven littering habits, undermine sustainability efforts.

- Cost Barriers: High costs associated with recycling technologies and sterilization processes can be prohibitive, especially in low-income regions.

Overcoming these challenges will require coordinated efforts among governments, businesses, scientists, and the public.

How Businesses and Organizations Can Take Action

Workplaces and institutions generate large volumes of PPE waste, making their participation critical. Steps to promote responsible PPE disposal include:

- Establish PPE Waste Policies: Create and enforce protocols for safe segregation, handling, and collection in the workplace.

- Engage Certified Waste Contractors: Partner with specialized firms experienced in safe disposal and recycling of biohazardous waste.

- Implement Green Procurement: Source eco-friendly or recyclable PPE products wherever possible.

- Staff Training: Regularly update staff on the latest disposal techniques to prevent contamination and to support zero waste goals.

The Role of Individuals in Reducing PPE Waste

Every person's actions count in the mission to turn PPE waste into no waste. Here's how individuals can contribute:

- Choose Reusable PPE: Opt for washable masks and durable face shields when suitable. Follow care instructions to ensure effectiveness and longevity.

- Dispose Properly: Always place used disposable PPE in designated bins, never littering or mixing with recyclables unless guidelines allow.

- Participate in Take-Back Programs: Look for community collection points or retailer initiatives that responsibly collect PPE for safe disposal or recycling.

- Spread Awareness: Educate friends, family, and colleagues about responsible PPE disposal practices and their environmental benefits.

Your small habits collectively create big positive impacts!

PPE Waste and Regulatory Guidelines

Different countries and jurisdictions have established regulations to control the management and disposal of PPE waste. Generally, these guidelines emphasize:

- Safety for Waste Handlers: Ensuring those who collect and process PPE waste are properly equipped and trained.

- Documentation and Tracking: Keeping detailed records of waste generation, handling, and final disposal.

- Compliance Enforcement: Imposing penalties on improper disposal or lax handling practices.

It's critical for organizations and waste management companies to stay updated on relevant regulations to avoid legal issues and environmental damage.

Future Outlook: Towards Zero PPE Waste

The goal to turn PPE waste into no waste is ambitious but achievable with ongoing innovation, strategic investments, and behavioral change. Some promising trends include:

- Biodegradable PPE: Research is ongoing into biodegradable face masks and gloves made from plant-based materials, which could dramatically reduce waste in the future.

- Extended Producer Responsibility (EPR): Policies requiring producers to take back and recycle their products are gaining traction in the PPE industry.

- Global Cooperation: Cross-border partnerships are enabling technology transfer and the sharing of best practices in PPE waste management.

Sustainable PPE waste practices will not only protect the environment but also facilitate stronger public health systems in the face of future challenges.

Conclusion: Take the Lead in PPE Waste Reduction

Turning PPE waste into no waste requires collective action, innovation, and responsible behavior at every level--from manufacturers and healthcare providers to individuals at home. By adopting eco-friendly PPE disposal techniques, supporting recycling initiatives, and prioritizing education, we can safeguard the earth for future generations while maintaining essential health safety standards.

If we all commit to responsible disposal practices, PPE waste can transform from a growing problem into an opportunity for sustainable development and resource recovery.

Let's embrace the challenge--because every mask, glove, and gown responsibly disposed of brings us one step closer to a safer, cleaner, zero-waste world.